Understanding AC Functionality

You may have often wondered, so how does car AC work. On the surface, an air conditioner seems like a simple utility—just push a button, and the machine starts to condition the air in your cabin. It keeps the airflow regulated for the right temperature and ensures there is no humid content, making the environment cool and comfortable. However, the internal aspect of the functionality is far more complex and fascinating. Every part inside works in sync, using clever mechanics to produce that refreshing breeze while controlling temperature, humidity, and airflow effectively.

From my observation, understanding the internal approach helps you dig deeper into why the AC is such a reliable machine. The car AC functions by cycling air, compressing, expanding, and cooling it through its components to maintain a consistent cool environment. Once you know how each aspect—external simplicity and internal complexity—works together, it becomes clear why the air conditioner is an amazing utility in both cars and homes, giving you comfort on hot days while making every drive pleasant.

How Does Car AC system Work? Understanding the Components

A car AC system is made up of several components that work together to keep your cabin cool and comfortable. The main parts include the compressor, condenser, evaporator, expansion device, and fan — each playing an important role in the cooling cycle. The refrigerant, a special liquid, travels through these parts, changing from gas to liquid and back again. As it moves, it releases heat outside and pushes cool air into the cabin, creating that refreshing feeling during hot weather.

From my years of observing how these systems function, the refrigerant truly acts as the blood of the process. It passes through every component with respect to the pressure and temperature changes, making the system efficient. The compressor pushes the refrigerant through the cycle, while the condenser helps release heat, and the evaporator absorbs it. Each device and fan works in sync, ensuring that the air inside remains pleasantly cool. It’s a fascinating mix of engineering and precision, all happening behind the dashboard without most drivers even realizing it.

Refrigerant

In every car air conditioning system, the refrigerant acts as its lifeblood, flowing through the entire system to keep you cool and comfortable even on the hottest days. Its unique ability to change from gas to liquid and then back again is what makes your AC work efficiently. The refrigerant absorbs heat from the interior, radiates it outside, and then returns cooled, always ready to absorb more heat again. This continuous cycle keeps the air inside your car pleasantly chilled while maintaining the balance between temperature and pressure.

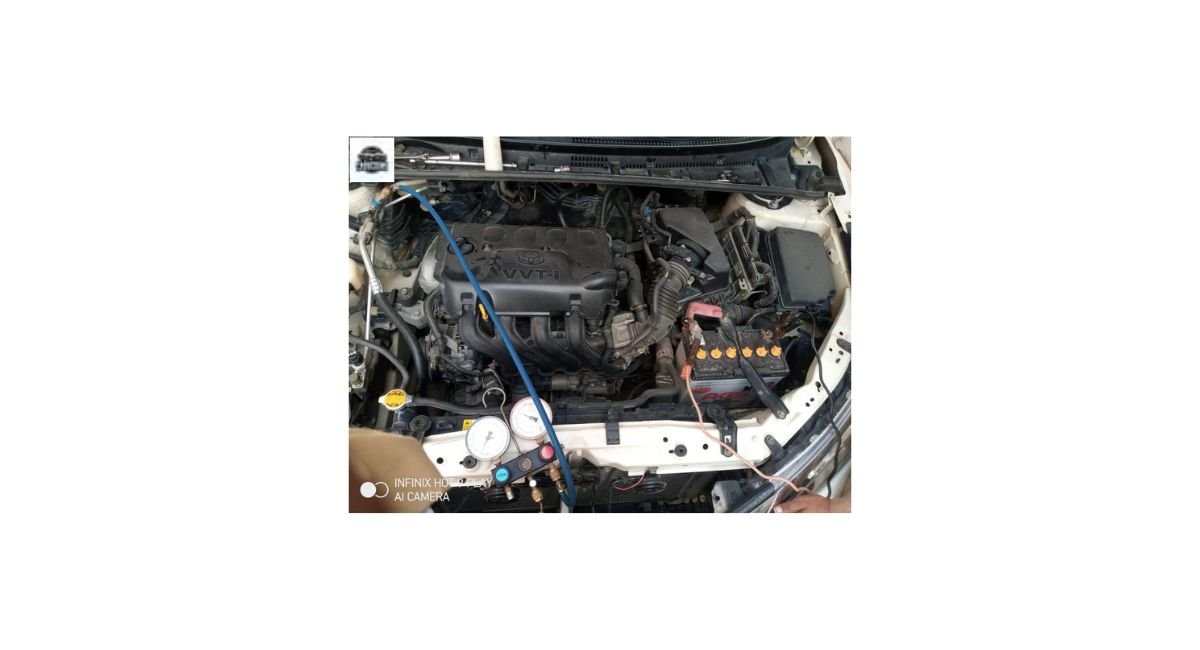

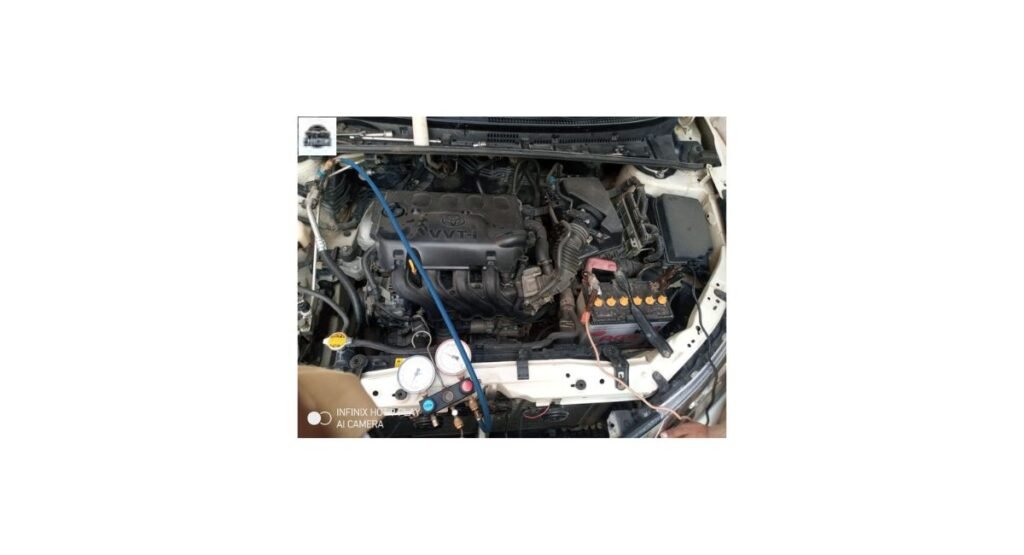

From my professional observation, most car air conditioning problems occur due to refrigerant leaks. These leaks are a common cause of reduced cooling and inefficiency. During any service or repairs, an experienced Natrad technician will check the refrigerant levels, repair any leaks, and refill the system as required. Keeping these levels correct ensures that your AC continues to perform at its best, providing a comfortable drive every time, no matter how warm it gets outside.

Compressor Functionality

To truly grasp how does car AC work, it’s essential to understand the compressor. Think of it as a pump that functions to compress the gas in the system. This component is attached to the crankshaft to receive power and perform efficiently. The refrigerant first enters the compressor in gaseous form, and the compressor does its work by compressing this gas to send it to the condenser for the next stage of the cooling procedure. It’s important to remember that the compressor can only handle gases and not liquids, which ensures the system runs smoothly without damage.

From my hands-on experience, the compressor is like the heart of the AC system—without it, the refrigerant cannot move, and the airflow cannot be properly cooled. Every compressing action ensures that the gas is pressurized correctly before reaching the condenser, maintaining consistent temperature control and efficient cooling. Observing this process gives you a real appreciation of how mechanical components work in perfect sync to keep your cabin comfortable on hot days.

Condenser Role

The condenser in an automotive air condition system works to condense the compressed gas from the compressor into a liquid. As the gas enters the condenser, some heat is created, but the tubes carrying airflow cool the gas, turning it into a high-pressure liquid. This liquid is then ready to enter the next component, the receiver, continuing the AC cycle. It’s interesting to note that the AC does not directly create cool air; instead, it takes the heat and moisture away from the cabin, leaving the air cool and comfortable.

From my experience, understanding the condenser helps you see how each component plays a part in maintaining cabin comfort. All components work together to dissipate heat and humidity outside the car, which is what keeps the interior consistently cool even on hot days. Watching this process in action reveals the clever design that ensures the air condition system functions efficiently, making every drive more pleasant.

Receiver-Dryer Function

The receiver in a car AC system acts as a reservoir that prepares the liquid refrigerant so it can be transferred to the evaporator. Inside, it contains desiccant, a drying agent, which absorbs any water or moisture in the system. That is why it is also called a dryer. Removing water at this stage is vital, because if the moisture is not removed, it can turn into ice crystals and ruin the entire air conditioning system.

From my experience, the receiver-dryer is a small but crucial component that ensures the system runs smoothly. By keeping the refrigerant free from moisture, it prevents damage and maintains efficient cooling. Understanding this part helps you appreciate how every component in the AC system works together to keep your cabin comfortable even in extreme heat.

Thermal Expansion Valve Role

The expansion in a car AC system works to expand the liquid by turning high-pressure refrigerant into low-pressure before it reaches the evaporator. This component further prepares the liquid so the valves can recognize the low-pressure and get ready to regulate the flow accordingly. From my experience, this small yet crucial valve ensures that the liquid enters the evaporator at the correct pressure, which is essential for maintaining efficient cooling and consistent cabin comfort, showing how every component works together in harmony.

Evaporator Function

The evaporator is placed inside the cabin and has its own parts like tubes and fins, all designed to absorb heat. The low-pressure liquid comes from the expansion valve into the evaporator, where the temperature stays around 32 degrees Fahrenheit or 0 degrees Celsius, so the liquid does not freeze. Because the liquid has a very low boiling point, it soon turns into gas, making it capable of absorbing much more heat from the car.

Once the gas leaves the evaporator, it carries the heat out of the cabin, while the blowing fan helps flow the cool air, letting you receive the charm of air condition. This gas then enters the compressor, and the cycle continues until you switch off the AC. From my observation, the evaporator is essential because it transforms liquid into gas efficiently, maintaining consistent cooling and comfort in the cabin, showing how every component in the AC system works together.

Refrigerant Lines in a Car AC System – Connecting the Components

As you’ve already read a brief introduction to the major parts of a car AC system, by now you also know that refrigerant circulates through all these main components. To connect these parts together, different lines are used so the refrigerant can transfer from one component to another within the AC system. Primarily, this is done using three main lines, but depending on the vehicle’s design, these lines can be divided into more sections. Below, we will explore these lines in a bit more detail to understand how they help the system work efficiently.

Discharge Line – Carrying Hot Gas from Compressor to Condenser

When understanding the AC system through a diagram or by monitoring refrigerant circulation, the very first and most important line is called the discharge line. This line carries gas directly from the compressor to the condenser, playing a crucial role in the system’s operation. Typically, the discharge line becomes very hot during operation, as it transports high-pressure gas. Both ends of the line are usually made of silver metal, providing strength and durability, while the middle section is often a rubber pipe that allows flexibility and absorbs vibrations from the engine. This combination of metal and rubber ensures that the line can safely and efficiently transfer the refrigerant while withstanding the high temperatures and pressure generated in the compressor.

Liquid Line – Transferring Liquid Refrigerant to the Expansion Valve

As the name suggests, the liquid line is responsible for carrying liquid-form refrigerant from the receiver-dryer to the expansion valve. In modern vehicles, this line often incorporates a pressure switch, which not only cuts off the compressor when the gas pressure drops too low but also manages several other important functions essential for the AC system’s efficiency. You can read more about its detailed workings in one of CarAcGuro’s specialized articles. Typically, the liquid line is made from a 5/16-inch silver tube, which provides durability while allowing smooth refrigerant flow. When the AC system is operating correctly, the liquid line is usually slightly warm, indicating that the refrigerant is moving efficiently through the system and ready for proper cooling at the evaporator.

Suction Line – Returning Low-Pressure Refrigerant to the Compressor

The suction line plays a critical role in the AC system by carrying low-pressure refrigerant from the evaporator back to the compressor. For this reason, many technicians often refer to it as the return line. The ends of this line are usually made of silver metal, similar to the discharge line, while the middle section is fitted with a rubber tube that provides flexibility and helps absorb engine vibrations. In most systems, a low-pressure charging port is installed on the suction line, which allows for safe and convenient refrigerant recharge. When the AC system is running at full capacity, the suction line becomes very cold, often causing condensation to form on its surface, much like the outer side of an ice-cold glass of drink, indicating that the refrigerant is efficiently returning to the compressor to continue the cooling cycle.

System Overview and Component Functionality

A car AC system works through the coordinated effort of each component, ensuring that the interiors remain comfortable in any weather. Every part contributes to cooling, heating, or defrosting the windshield, and the overall system is carefully controlled by a computer known as the climate control system. From my experience, understanding how the refrigerant moves, how the compressor pressurizes the gas, and how lines like discharge, liquid, and suction lines connect all components gives a clear picture of how efficiently the system operates.

Even though it seems complex, the process is designed to be simple in function: the refrigerant absorbs heat, releases it outside, and cycles continuously to provide a stable temperature inside the car. By breaking down each component’s role, it becomes easier to see how the AC system maintains comfort, ensures proper airflow, and regulates interior temperature effectively. This process, when explained step by step, is straightforward enough for anyone to understand and appreciate the engineering behind a modern HVAC system.

People also ask

1. How does AC work in a car step by step?

A car AC works in four simple steps:

1. The compressor pressurizes the refrigerant and sends it forward.

2. The condenser cools the hot refrigerant gas and turns it into liquid.

3. The expansion valve reduces pressure to make the refrigerant colder.

4. The evaporator absorbs heat and blows cool air into the cabin.

—

2. Is 72 degrees cold for AC?

Yes, 72°F (about 22°C) is considered a cool and comfortable temperature for most people. Many set their AC between 72–75°F.

—

3. What is the basic working principle of AC?

An AC works on the heat transfer principle. It removes heat from the air inside and releases it outside, sending cool air back into the room or car.

—

4. What are the 5 main AC parts in a car?

The five main parts of a car AC are:

1. Compressor

2. Condenser

3. Expansion Valve / Orifice Tube

4. Evaporator

5. Receiver Dryer / Accumulator

—

5. What are the 4 steps of AC?

The four steps of an AC cycle are:

1. Compression

2. Condensation

3. Expansion

4. Evaporation

—

6. Which gas is used in car AC?

Most cars use R134a, while newer models use R1234yf refrigerant.

—

7. What controls car AC?

The car AC is controlled by the Climate Control System or AC Control Panel, which includes:

Temperature settings

Fan speed

Mode selection

Sensors

ECU commands

—

8. What is the most expensive part of a car AC?

The most expensive part of a car AC is the compressor, as it is the main component that drives the entire cooling process.